Transform PLA into compostable coffee capsules directly in your own company

Transform PLA into compostable coffee capsules directly in your own company

An integrated solution for single-serve coffee production: from encapsulation to packaging, reduce costs, comply with EU regulations, and promote a future free of microplastics. Your coffee, your production, our sustainable technology.

A complete in-house solution

From PLA raw material to a packaged single-serve coffee capsule, ready for sale on the market

From PLA (Polylactic Acid) granules used to produce the compostable capsule, to the coffee encapsulation process and the packaging of the finished product, we offer a complete solution that enables companies producing single-serve coffee capsules to integrate the entire production process in-house. This approach helps reduce costs, ensures compliance with European regulations, and actively contributes to reducing microplastics in the environment.

An Italian company that cares about the health of the environment

DE PLANET ITALIA is an Italian company specialized in designing production processes for the manufacturing of single-serve compostable capsules for hot beverages, particularly coffee. Its mission is:

Extensive experience in the compostable products market

Founded after more than 15 years of experience in the compostable polymers market, De Planet Italia has gained in-depth knowledge of the industrial and commercial processes in the single-serve capsule sector. It has developed an innovative and sustainable production cycle for companies that wish to be competitive and comply with European green regulations.

A comprehensive and scalable industrial process

DE PLANET ITALIA has developed a complete and scalable industrial production process for the creation of compostable coffee capsules made from PLA (polylactic acid), a biodegradable polymer derived from renewable sources such as corn starch or sugarcane.

Thanks to this innovative technology, coffee-producing companies can integrate the entire production cycle directly within their facilities: from the transformation of PLA granules into capsules, to the coffee encapsulation process, and finally, the packaging of the finished product. This system combines sustainability, efficiency, and compliance with European regulations, while simultaneously reducing operational costs and environmental impact.

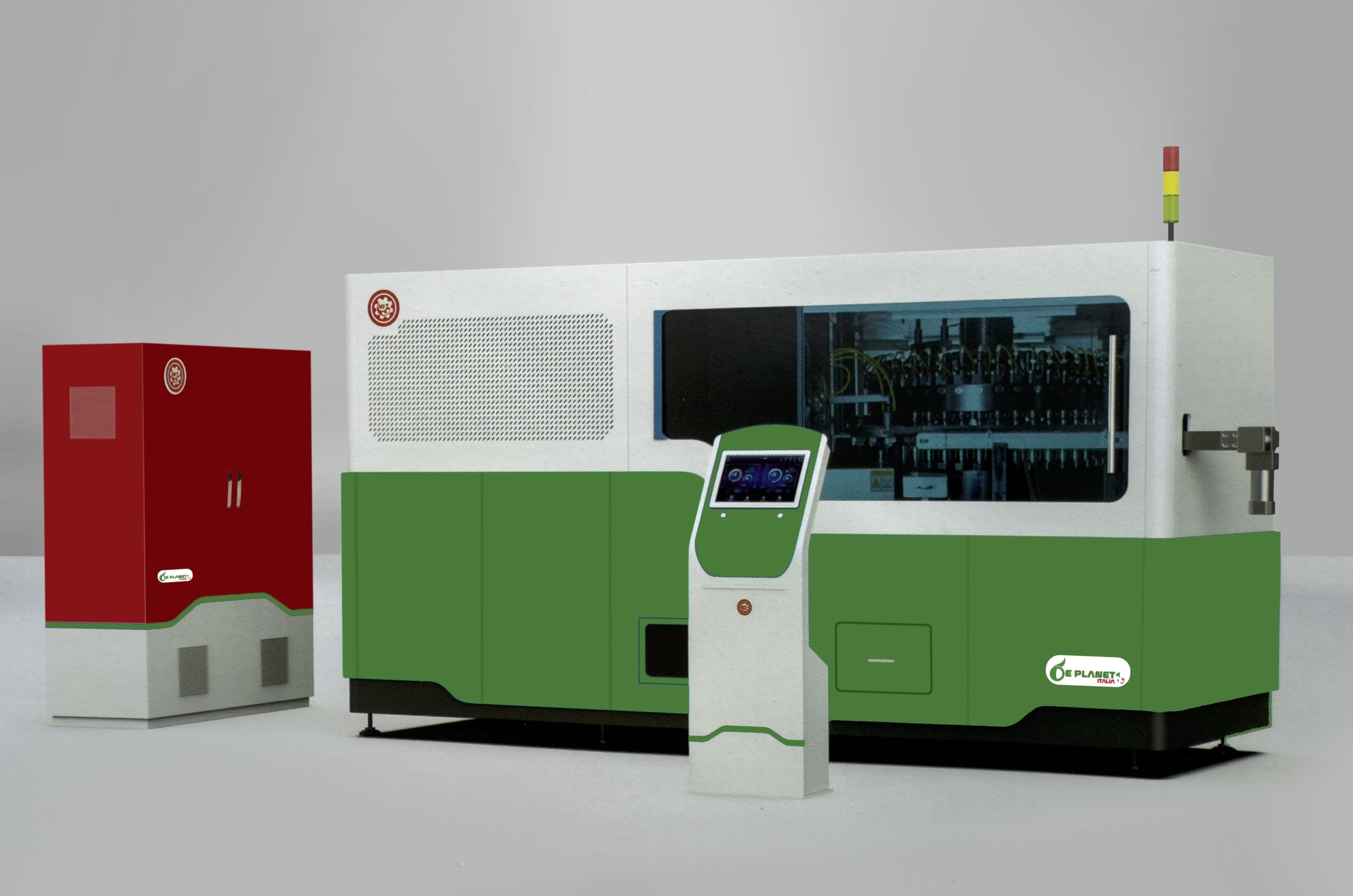

Machines for encapsulation and packaging of capsules on a 5-year free loan

DE PLANET ITALIA offers the machinery for the production of compostable capsules, including encapsulation and packaging of the finished product, on a free loan basis for 5 years. This allows companies to produce compostable capsules directly within their facilities, ensuring the same quality at the same cost as traditional plastic or aluminum capsules.

Free Loan Equipment

The machinery for the production of PLA capsules is provided free of charge for 3 years to companies, allowing them to produce compostable capsules without bearing the initial investment costs, purchasing only the polymer for capsule molding.

Exclusive PLA Granules/Polymers

DE PLANET ITALIA has a strategic partnership with HISUN, one of the leading producers of compostable PLA polymers in China, ensuring a constant supply of high-quality compostable polymer.

Unique Crystallization Process

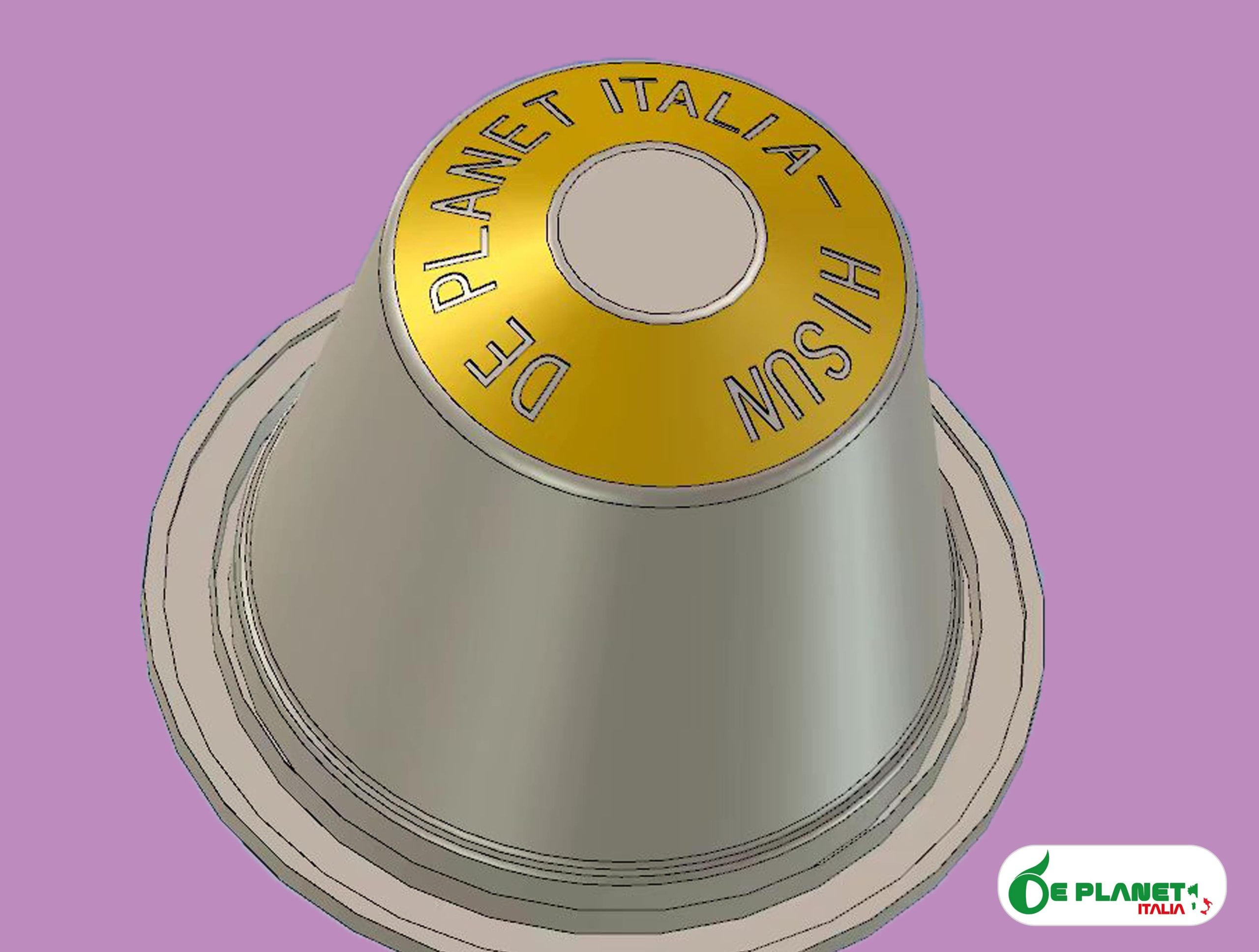

After the compression molding, DE PLANET ITALIA uses an innovative crystallization process that gives the compostable capsules superior technical properties during extraction in all Nespresso-compatible coffee machines on the global market, particularly in terms of heat resistance and seal integrity.

24/7 Technical Support and Maintenance

The maintenance of the machinery is guaranteed by TECNOPACK Srl, a company with 30 years of experience in the packaging machine sector, providing technical support and training for the staff of client companies 24/7.

Certifications of Raw Material and Finished Product Capsules

The CSI laboratories in Milan have analyzed and are in the process of issuing the CSI COMPOSTABLE INDUSTRIAL certificates for the compostable capsule used after extraction, which disintegrates within the terms and timeframes required by European regulations.

DE PLANET ITALIA Patented Single-Serve Compostable Capsules

DE PLANET ITALIA capsules are patented in all countries worldwide and offer the guarantee of compatibility with all Nespresso-compatible coffee machines.

Benefits for Client Companies

Internal Production

Internal Production

Coffee-producing companies can integrate the production of compostable capsules within their facilities, eliminating external procurement costs and improving control over production processes.

Cost Reduction

Cost Reduction

Thanks to the exclusive partnership with HISUN, a leading Chinese company in the production of compostable polymers, DE PLANET ITALIA is able to offer the polymer for the production of compostable capsules at the same cost as traditional plastic capsules, overcoming the price increase typically associated with green solutions.

Environmental Sustainability

Environmental Sustainability

DE PLANET ITALIA’s single-serve compostable PLA capsules fully comply with European environmental directives, offering coffee-producing companies an eco-friendly alternative that enhances brand image and meets the demands of an increasingly sustainability-conscious market.

CSI COMPOSTABLE INDUSTRIAL Certifications under Personal Licensing

CSI COMPOSTABLE INDUSTRIAL Certifications under Personal Licensing

DE PLANET ITALIA’s client companies will receive their personal license for the compostable capsules, which, with the authorization of DE PLANET ITALIA, will be recognized by the CSI laboratories in Milan. This guarantees the ability to export their products made with DE PLANET ITALIA compostable capsules to all countries worldwide.

Subscribe to our newsletter

Subscribe to our newsletter

and you will receive all the latest news.